Automatic Sludge Dewatering Filter Press Machine for Solid

Basic Info.

| Model NO. | XMGZY-200/1250-30U |

| Style | Membrane Filter Press |

| Performance | Efficient Filtration |

| Certification | CE |

| Dimension | 4220*1300*1250mm |

| Thickness | 30mm |

| Warranty | 1 Year |

| Weight | 3580kg |

| Filter Area | 200m2 |

| Filter Pressure | 0.5MPa |

| Automatic Grade | Automatic |

| Voltage | 380V |

| Transport Package | International Standard Packing |

| Specification | hydraulic press |

| Trademark | LEABON |

| Origin | Henan, China |

| HS Code | 8421291090 |

| Production Capacity | 20set/Month |

Packaging & Delivery

Package Size 400.00cm * 200.00cm * 180.00cm Package Gross Weight 2500.000kgProduct Description

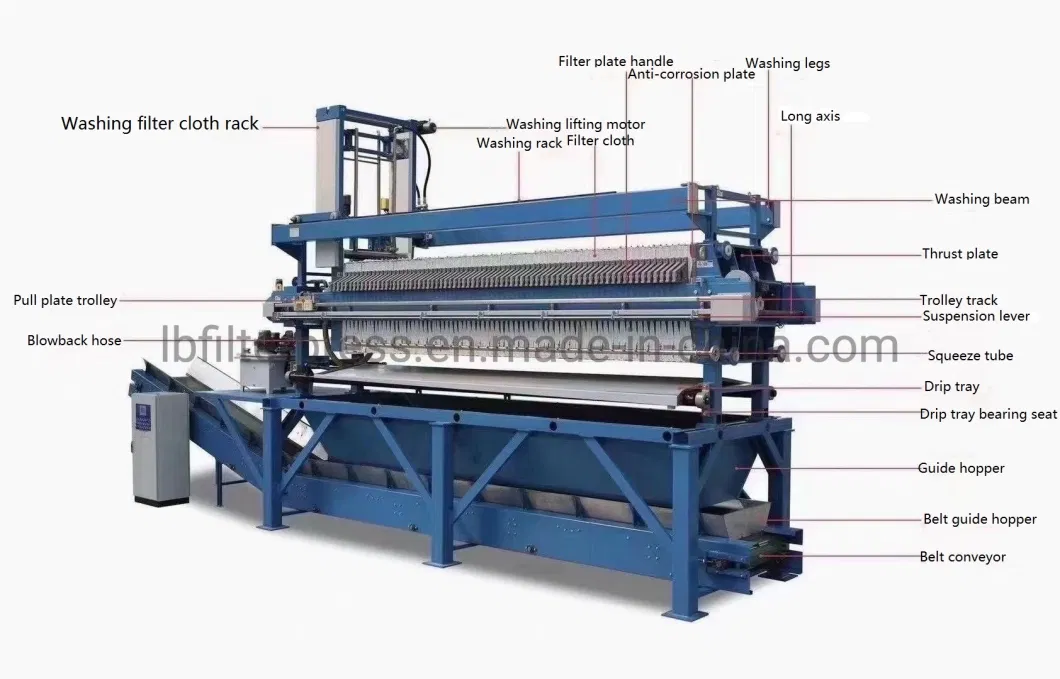

Automatic Sludge Dewatering Filter Press Machine For Solid-liquid SeparationApplicationThe membrane filter press is pressed by the external filter plate to form a closed filter chamber, and the solid-liquid separation is realized by the filter medium (filter cloth, filter paper, etc.) under the action of the feed pump.

Main Parameters:

model | Filter aream2 | Plate sizemm | Thickness of filter cakemm | Plate number pcs | Cubage of filter chamberL | Filter pressureMpa | Cylinder rated pressureMpa | cylinder maximum strokeMpa | Foundation Dimensions | Dimensions | weightkg | |||||

| L1mm | Bmm | Cmm | Lmm | Wmm | Hmm | |||||||||||

| XMJ/520-20U | 4 | 520*520 | 20 | 9 | 40 | 0.5-1 | 25 | 350 | 1280 | 200 | 600 | 1880 | 830 | 850 | 560 | |

| 6 | 14 | 60 | 1510 | 2110 | 630 | |||||||||||

| 8 | 19 | 80 | 1730 | 2330 | 700 | |||||||||||

| 12 | 29 | 120 | 2210 | 2810 | 830 | |||||||||||

| 16 | 39 | 160 | 2610 | 3200 | 980 | |||||||||||

| 18 | 44 | 176 | 2840 | 3410 | 1160 | |||||||||||

| 20 | 49 | 200 | 3060 | 3650 | 1360 | |||||||||||

| BMJ/520-30U | 4 | 520*520 | 30 | 9 | 60 | 0.5 | 25 | 350 | 1450 | 200 | 600 | 2050 | 830 | 850 | 590 | |

| 6 | 14 | 90 | 1750 | 2350 | 660 | |||||||||||

| 8 | 19 | 120 | 2050 | 2650 | 760 | |||||||||||

| 12 | 29 | 180 | 2670 | 3270 | 930 | |||||||||||

| 16 | 39 | 240 | 3210 | 3810 | 1100 | |||||||||||

| XMJ/720-25U | 20 | 700*700 | 25 | 24 | 250 | 0.5-1.6 | 20 | 450 | 2200 | 460 | 800 | 3100 | 950 | 1100 | 2210 | |

| 30 | 37 | 380 | 2880 | 3800 | 2660 | |||||||||||

| 40 | 49 | 500 | 3500 | 4400 | 3080 | |||||||||||

| BMJ/700-30U | 20 | 700*700 | 30 | 24 | 300 | 0.5 | 20 | 450 | 2450 | 460 | 800 | 3350 | 950 | 1100 | 2300 | |

| 30 | 37 | 450 | 3230 | 4070 | 2800 | |||||||||||

| 40 | 49 | 600 | 3950 | 4900 | 3500 | |||||||||||

Product Usage

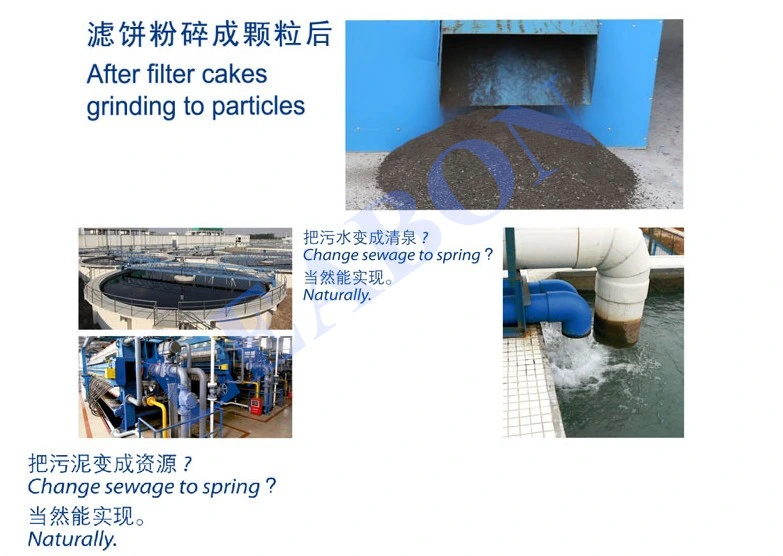

The diaphragm filter press is pressed by the external filter plate to form a closed filter chamber, and the solid-liquid separation is realized by the filter medium (filter cloth, filter paper, etc.) under the action of the feed pump. The equipment is widely used in the fields of petroleum, chemical, pharmaceutical, pharmaceutical, food, starch, dye, coal mine and other industries for water treatment and dehydration.

Diaphragm filter press is an intermittent pressurized filter device for solid-liquid separation of various suspensions.Sewage: electroplating wastewater, steel mill wastewater, electroplating sludge treatment, municipal sludge dewatering, water plant wastewater, dust removal wastewater, printing and dyeing wastewater, papermaking wastewater, biological wastewater, port sludge, red mud, leather wastewater treatment, kaolin, ceramics, clay ;Medicine: raw material medicine, proprietary Chinese medicine;Chemistry: basic chemicals, gypsum, soap, pesticides, mercury, sodium chloride, waste acid recovery, catalysts, cesium chloride;Food: edible oil, palm oil, palm kernel oil, vegetable butter, finished syrup, raw sugar, beet sugar, sucrose, soy sauce, juice pectin;Minerals: iron ore, manganese chloride, calcium carbide slag, zinc chloride, calcium hypochlorite, electrolytic manganese, waste acid recovery, calcium carbonate, industrial sand, gold mine tailings, salt mud, aluminum phosphide, potassium chloride;

Workshop

Our Service

1. supply the free material testing in laboratory and give out the report for free. 2. supply free model selection according to your capacity and other information.3. supply manual operation to insturct the operation.4. supply installation instruction. 5. supply full set of filtration solution . We have top pump , valve , motor agreement supplier , can give you turnkey service.

FAQ:

1. How to buy your interested products?You can provide us the slurry sources, flow rate and ground area, material requirements about your project (More details, please contact us).2. How to pay? L/C or T/T are acceptable. 3. What is the delivery time?It depends on order quantities. Generally speaking, the delivery time will be within 2 months.4. How to pack the products?We use standard export package. If you have special package requirements, we will pack as you required, but the fees will be paid by customers.5. How to install after the equipment arriving destination?We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.6. How long is the validity?The validity is 12 months after installation.

Related products